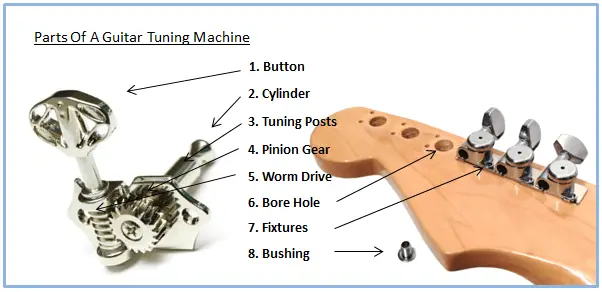

Did you know there are over TEN components of a tuning machine?

What are the parts of a tuning machine? The tuning machine is made from tuning head, cylinder, tuning posts, bore hole, pinion gear, worm drive, bushing, button, rubber casing and lock-in screw to make it function.

In this article, I will discuss these in more detail.

1. Button (Tuning Head / Grip Piece)

The button is also known to be called the tuning head and the grip piece. It is the part of the machine head that your hands grip to loosen or tighten the string.

When you are putting on new string, you will turn the tuning grip piece clock-wise to tighten it. If you keep twisting it in this direction, you will eventually increase the tension of the strings and reduce the slack.

If you want to change and remove your strings then you will turn the tuning grip piece anti-clockwise.

There are many variations of the button. This includes the colour and the material. They can come in many colours as you can imagine but the modern ones are mainly plated in gold or silver. They can also come in two main materials being steel alloy or plastic.

2. Cylinder

The cylinder is the part that holds the strings and is where the strings coil round repeatedly.

You have two types of cylinders the vintage tuners Some cylinders are designed better than others. The cylinder has to be designed to hold the string securely and are slanted to push the strings to the center of the piece.

This is because the strings want to be reeled as close together as possible to avoid string slippage.

String slippage is impossible to avoid, however some designs do work better than others do.

3. Tuning Posts

Tuning posts is an important component of your machine and they are generally TWO types of these. The Tuning posts usually vary depending whether you are using the vintage or modern style tuning machinehead.

For example, the original Kluson branded tuning machine (typically used on the Fender Stratocasters) have a slot in the top of the post (being the cylinder) with a hole running down the center of the shaft where the string is then placed.

Whereas, the sealed machine post has a hole in the post (being the cylinder) that threads the string through and then over the post repeatedly until the string coils over itself. These require a bit of skill to re-string as cutting the unused string can sometimes be messy.

Overall, the slotted vintage style is still popular today and many players prefer the design for their vintage aesthetics in addition they are also easier to re-string. They also have the added bonus that the trimmed end of the string being hidden and does not stick out. Whereas, you may catch your fingers and tear up the inside of your gig bag with the sealed machine.

4. Bore Hole

The bore hole refers to the six large holes in the headstock which allow the tuning posts to pass through.

Generally, every guitar will have SIX bore holes and bass guitars will have FOUR bore holes. This is to accommodate for holding each string in place.

The bore hole is dependent on the amount of string you have. So, if you have a seven-string guitar then your will have seven bore holes. The same goes for a five-string bass etc…

The bore hole’s size can vary depending if you are using a traditional or sealed machine and the type of bushings used to hold the machinehead in place from the font of the headstock.

The sealed machine usually have a 10mm threaded bushing with surrounded washer and held to the headstock by a single screw piece. Whereas, the traditional machines will fit into ¼-inch holes on the headstock.

5. Pinion Gear

The pinion gear is the gear wheel that attaches to the post and the worm drive.

When tuning your guitar the pinion gear turns clockwise and anti-clockwise depending on the direction you twist the tuning head / grip piece.

The pinion gear fixes onto the worm drive that is responsible for turning the cylinder, which alters the tension of the guitar string.

6. Worm drive

The worm drive is like a screw mechanism that attaches between the pinion gear and tuning head / grip piece.

The contact between the worm drive and the pinion gear gives a ratio specification. This is determined by the gearing ratio (basically the size of the gears). The specification of the gears ratio determine how much movement is made when you turn the Tuning Head / Grip Piece.

For a standard guitar the gears ratio specification will vary between 14:1 and 18:1. For a standard bass guitar the ratio of the gears will be 20:1 to 24:1.

The higher the ratio, the more turns of the tuning head are needed. Those that provide less movement are actually better as you can find the correct notes more accurately.

7. Bushing

The bushing fastens the tuning post onto the front side of the guitar headstock from the front side of the guitar and they are responsible for holding the whole machine nut onto the headstock.

Moreover, there are TWO types of bushings being the push-in / press-in and bolt threaded bushings.

- The push-in / press-in style bushings are found on the vintage types of machine tuners where the borehole located on the headstock is smaller.

- The Bolt threaded bushings are found on the modern sealed tuning machines where the post has a larger diameter to provide greater support for the tuner shaft. This means the bore hole on the guitar headstock must also be bigger to accommodate for the sealed machine

However, because of the two different size bushings can cause a problem if you want to revert to the traditional tuning machine. But, there is good news because it is common to find conversion bushings to make the bore hole to its original size.

8. Fixtures

The fixtures are referred to the screw or indexing pin.

On most guitars, a screw is used to tightly hold the machine in place so it does not wobble and fastens the machine to the headstock.

Whilst the Indexing pins are less common they consist of a pin instead of a screw to hold the machine in place. They have their advantages of not being fixed to the guitar because screws tend to thread over time. But they can often fall out and get damaged when changing the strings as they are held in place by the tension of the guitar strings.

9. Rubber casing (sealed machines tuners)

Rubber casing are only found on sealed machines, they are used to prevent dirt, and moisture getting inside the gear system as it can weakening it over time.

The rubber casing also is used as it keeps the gear lubricated. A well lubricated gear is smooth when adjusting the string.

10. Lock-in Screw (guitars with a Whammy)

The lock-in screw (locking machine) is an attachment on the machinehead that is mainly found on guitars with a whammy (however this is not always the case).

The lock-in screw can increase the tuning stability as it locks traps the strings. By doing so it prevents the strings from slipper over time.

This works by a wheel mechanism on the back of the tuner. When a string is threaded through the cylinder on the post, the rear wheel is turned clockwise to effectively ‘pinch’ the string and lock it in position.

Even though it decreases the flexibility of your tuning, lock-in screw are becoming more popular especially guitar with a whammy or Floyd rose.

Conclusion

In this article, we have discussed every component that makes up the common tuning machinehead, were we discussed in detail about…

- Button

- Cylinder

- Tuning Posts

- Bore Hole

- Pinion Gear

- Worm drive

- Bushing

- Fixture

- Rubber casing (sealed machines tuners)

- Locking screw (guitars with a Whammy)

I hope you enjoyed the post and please leave comment on anything I did not explain as well as I should have.

Thanks and have a wonderful day J

Is there a part number “cross reference” for replacement tuning machines by brand (Grover, Planet Waves, Schaller, Sperzel, Gotoh, etc.?) Im trying to find an aftermarket, upgraded, premium (18:1 or better) set of 3+3 tuning machines to replace my old factory winders on an acoustic. I have the specs, and i am trying to avoid drilling any new holes. I also have a StewMac part# and a Proline part# (that will both fit my guitar, but they are cheapy 14:1) to cross-reference over to a Grover, Planet Waves, Schaller, Sperzel, or Gotoh, etc?

if you have measurements of the bore holes then i would go to a specialised store and ask them if they have the size in question. it is common online to find the vintage size post holes for even sealed machines. Otherwise, if you have to drill then you can get Bushing that will allow your old tuning pegs to fit snug if you want to change them out again.

Hi Richard,

My 20th Anniversary Fender Squier Strat (2002) has the standard machine heads (modern sealed gear tuners I think). I was tightening the budgets (looks like your basic nut) on the front of the headstock today and I overtightened one. Now it won’t tighten and it’s really loose. I tried to loosen it enough to remove the entire machine head but it won’t come off. The busher just keeps going round and round and round. What do I have to do? Thanks for your articles, and in advance your help.

Hi Shaun, thanks for your comment.

Very nice guitar btw!

It sound to me like you have threaded the groove either on the “outside of the bushing” or at the “bass of the tuning post”, (where the bushing screw into).

if the threading appears on the bushing you might be able to get a file and correct the threaded groove (difficult tasks but it can be done).

otherwise if the threading is on the base of the tuning post then there is nothing you can do.

There are other small fixes you can do but i would not recommend (like apply wood glue, or force it with some pliers) as it give you tuning problems and cause permanent damage.

All in all, i would invest in a new pair. if on a budget you can pick some Grovers up for cheap.

https://www.stewmac.com/parts-and-hardware/tuning-machines/solid-peghead-guitar-tuning-machines/grover-original-rotomatics-102-series-3and3-tuners.html?utm_source=google&utm_medium=shopping&utm_campaign=2020-09-gp&pref_currency=P&shipcalc=UK&gclid=CjwKCAjwh7H7BRBBEiwAPXjadtVp-nfkqFdeOg3HwHzKFpuHsSI-sCUW5sztzktKz9tL_7L1QtaVHhoCl1EQAvD_BwE

or get some signature Fender ones.

https://www.gear4music.com/Guitar-and-Bass/Fender-Locking-Stratocaster-Telecaster-Tuning-Machines-Chrome/QXO?origin=product-ads&gclid=CjwKCAjwh7H7BRBBEiwAPXjadrqthuYGBiz7kDlmJxg1KNkGqG-n2JGBBd57TUQb4IxbviZDOWJ3JxoC8vAQAvD_BwE

Please keep me updated what you decided 🙂

Sorry, when I said budgets I meant bushers.

Thanks Richard. The first link allowed me to see the whole busker. I thought it was just a nut. Well let you know how I go. Not sure how I’m going to get it off to inspect though.

First budgets, then buskers. Wonder what’s next, oh so intuitive Samsung keyboard, recently updated and starting to learn all over again (and get on my nerves).

Anyway, I got the tuning machine off. The website I’ve included in the website field of this post is a link to a pic in my Dropbox which shows a pic of the parts to the machine head and the hole in the headstock that’s left.

From the left (15th fret), this is the busher, aka budget or busker 😛 that I was turning. [For your readers:] the screw end of that goes through the washer on the 14th fret all the way until the nut end rests on the washer. Then the peg/post (13th fret) goes through the busher from the screw end and you screw the busher into the part on the 12th fret (busher receiver, idk?!).

The problem was, I believe the ring on the 11th fret, if you zoom in, has 3 welds that are supposed to be welded onto the bottom end (the end shown) of the “busher receiver”, but it had broken off in all 3 places. Maybe it was stuck in the wood as you can see 3 matching weld-size spots of damage around the hole in the headstock. Maybe it’s supposed to be. In any case, my over-tightening of the busher has caused the welding spots to break, so there was no resistance from the “busher receiver” when I was trying to unscrew the busher; the “busher receiver” just kept going round and round.

To finish the story [for your readers], the other side of that ring rests around that lubed part of the gear you can see there. The gear gets screwed in (on a vintage tuner this would be an indexing pin, am I right?) to the bottom of the peg/post after you’ve secured the “busher receiver” in the bore hole from the underside of the headstock and screwed the combined peg/post, washer and bushing into it. Finally, the button/tuning head/grip piece (with in- built worm drive not visible in the pic) actually just pops onto the “busher receiver and houses the gear, which locks into the teeth of the worm drive.

There’s the hint as to how I got the whole thing off. I had actually already tried the pliers before you said not to Richard, but only lightly. It was clear it wouldn’t work. As there was daylight between the tuning head and the headstock, I slipped something flat and hard in between (don’t ask) and popped the tuning head off. Then I could see everything and it was just a matter of unscrewing the screw that screws the gear into the peg/post. Nothing like a bit of trial and error (phew!). Good thing I am somewhat intuitive (or maybe just lucky).

Final question, Richard, are those grooves in the headstock from the welding spots a cause for concern?

Thanks again mate.

Hello Richard, do you know of any place where you can order just a tuning post and pinion gear for 3-in line acoustic tuners? I have a ‘30s May Bell parlor guitar that just needs a post and gear for one tuner. Thanks in advance!

Hi Eric, I had this same problem. I lost a locking nut off my strat tuners and had to buy a whole new set.

For a cheap fix you can buy singles but they won’t match the original set. You might be able to find something on eBay or Facebook market place. But I really doubt that.